Blasfolien, Flachfolien- & Plattenextrusion

85 Jahre Erfahrung im Maschinenbau und Anlagenbau.

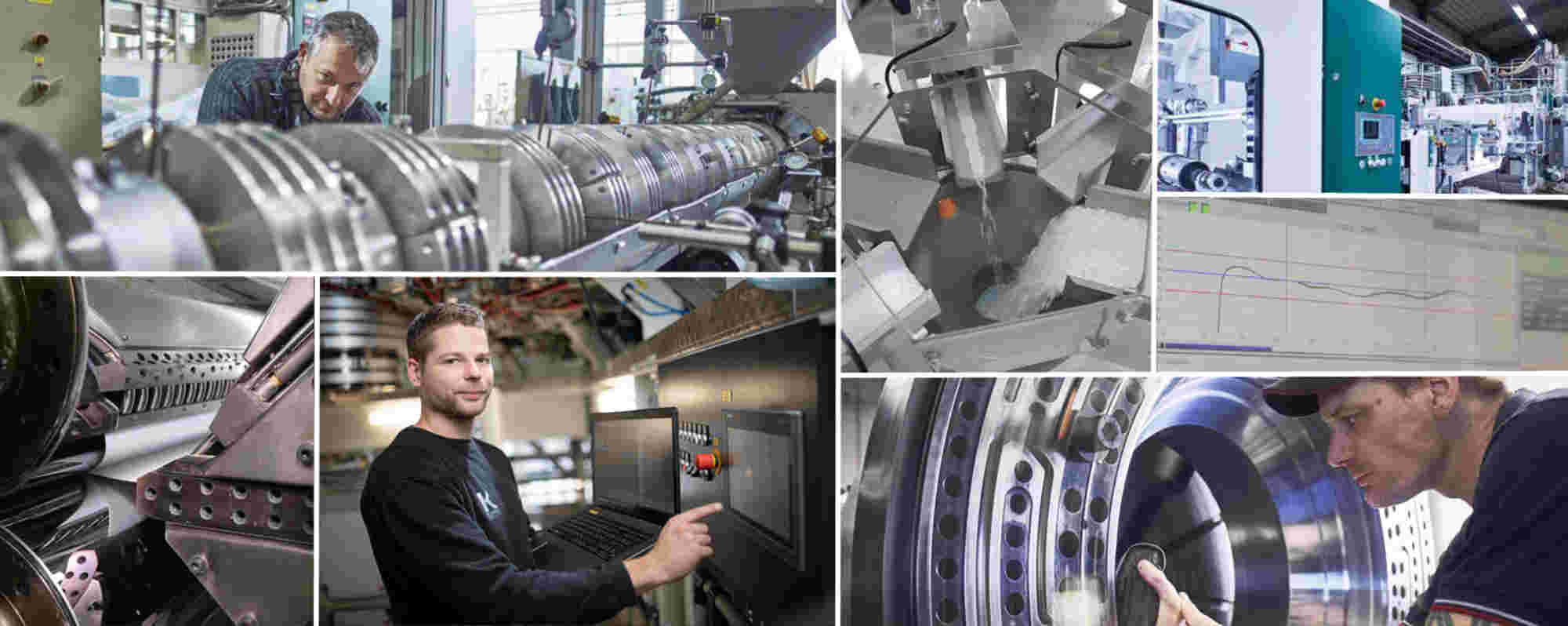

KUHNE Group zählt zu den führenden europäischen Maschinenbauern für die Folien- und Plattenherstellung.

Egal ob Sie eine biaxial verstreckte Hochbarrierefolie für Frischfleisch, eine extrem dünne Kaschierfolie aus HDPE, eine EVA-Folie für medizinische Zwecke, eine Noppenfolie, eine PET-Folie oder eine Schaumplatte für die Bauindustrie herstellen möchten, bei uns bekommen Sie die perfekte Maschinenlösung – und zwar inklusive Verarbeitungs-Know-how.

Mit ihren Unternehmen KUHNE Maschinenbau, KUHNE Anlagenbau und K-Tool ist die KUHNE Group bestens aufgestellt und kann alle Anforderungen, die an einen modernen Extrusionsanlagenhersteller heute gestellt werden, erfüllen.

KUHNE Maschinenbau

Ob In- oder Offline, Folie oder Platte: Unsere Maschinen machen den Unterschied. Moderner Maschinenbau zur Entwicklung langlebiger, leistungsstarker Lösungen in Schlüsselindustrien – in den Bereichen Verpackungen, Medizin, Pharmazie, Biotechnologie, Energie- und Baubranche oder Automobilindustrie.

KUHNE Anlagenbau

Wir sind ein mittelständisches Maschinenbauunternehmen, welches sich auf innovative Blasfolientechnologien spezialisiert hat. Seit über 30 Jahren finden wir Lösungen für komplexe Anforderungen unserer Kunden. Für alle Typen von Blasfolienanlagen haben wir ein modulares System aus Standardkomponenten entwickelt. Dies garantiert Ihnen neben einem Preisvorteil vor allem ein Höchstmaß an Flexibilität.

KUHNE K-tool

Das Unternehmen verfügt über einen hochmodernen Maschinenpark mit über 30 Mitarbeitern, die auch vor schwierigen Aufgaben nicht zurückschrecken. Suchen Sie höchste Qualität mit bester Fachkompetenz – wir haben sie.

Unsere Erfahrung und Leidenschaft sind die Zukunft unserer Kunden.

Sie stehen mit Ihren Wünschen und Anliegen im Mittelpunkt, daher beraten wir stets technisch gut und gehen individuell auf Sie ein. Dabei sind auch die Maschinen und Extrusionsanlagen individuell nach Maß hergestellt.

Für Sie entwickeln und produzieren wir maßgeschneiderte Produkte.

Komplette Turn-key Anlagen oder „nur“ ein Extruder, eine Schnecke, ein Glättwerk oder ein Blaskopf: Alle diese entscheidenden Bauteile werden von uns hausintern entwickelt und produziert – und das seit Jahrzehnten.

Vorteile der KUHNE Group

Wir erfüllen alle Anforderungen eines modernen Extrusionsanlagenherstellers. Denn die jahrzehntelange Erfahrung bei der Konstruktion, Planung und Fertigung unserer speziellen Maschinentechnologie befähigt uns auch, das angestrebte Endprodukt zu optimieren – von neuen und verbesserten Rohstoffen bis zu kundenspezifischen Produkten und Prozessen. An diesen arbeiten wir mit unseren rund 230 hoch qualifizierten, spezialisierten und erfahrenen Mitarbeitern gemeinsam mit unseren Kunden und Forschungsinstituten und schützen deren Einzigartigkeit über Patente und Gebrauchsmuster.

Wir führen eine konsequente und komplexe Umsetzung aller Aufträge in unserem Haus durch. Von der Planung über die Konstruktion bis zur Fertigung und Montage vor Ort. In aller Welt. Made in Germany. Im Gegensatz zu vielen Wettbewerbern halten wir selbst leicht auszulagernde Bereiche wie den Bau von Schaltschränken oder die Oberflächenveredelung im eigenen Haus. Wir fertigen von Teilkomponenten bis zu Komplettanlagen alles selbst. Nur so können wir die gleichbleibend hohe Qualität garantieren, die unsere Kunden und wir von uns erwarten – bei hohen Stückzahlen genauso wie bei kundenspezifischen Sondermaschinenlösungen.

Innovation, Neuentwicklungen und maßgeschneiderte individuelle Lösungen sind für uns dabei genauso selbstverständlich wie die solide und zuverlässige Ausführung von Servicestandards, die bei uns naturgemäß ein besonders hohes Level haben. Denn über den reinen Maschinenbau hinaus realisieren wir längst auch Turn-Key-Anlagenbaulösungen – von der Statik, Planung, Konstruktion und Klärung der Rahmenbedingungen vor Ort über den Bau von Produktionshallen, Laboren und Lagern bis zur Klärung der Frage von Energieträgern und -versorgern, der Logistik, Durchführung von Testreihen und Entwicklung eigener Rezepturen.

Jede unserer Anlagen entspricht internationalen CE- oder landesspezifischen Normen, die wir mit den jeweiligen Sicherheitsbehörden ausarbeiten – inklusive detaillierter Dokumentation und Bedienungsanleitung in der Landessprache oder einer Vorabnahme in unserem Werk. Gerade für sicherheitsrelevante Branchen wie die Lebensmittelindustrie, Medizin oder Pharmazie mit strengsten Regularien ist dies von besonderer Bedeutung. Genauso wie für „Clean-Room-Anlagen“ mit speziellen hygienischen, umwelt- und sicherheitstechnischen Aspekten und Normen, deren Realisierung ebenfalls zu unserem Leistungsspektrum gehört.

Kontaktieren Sie uns jetzt!

Sie suchen einen professionellen Hersteller für Ihre Extrusionsanlage? Dann sind Sie bei uns genau richtig! Melden Sie sich bei uns und wir erstellen ein für Sie angepasstes Angebot.

Aktuelles